Expert Chiller Services in Toronto, Canada

Comprehensive information about the use of chillers

Industrial chillers play a crucial role in cooling processes for various industries. Here’s how they work and why proper maintenance is essential:

Mechanical Compression Cycle: The chiller’s refrigerant moves through four main components: evaporator, compressor, condenser, and expansion valve.

De-superheating and Condensation: The condenser first de-superheats the high-pressure refrigerant vapor, bringing it to a saturated condition. Heat is transferred to lower the refrigerant’s temperature until condensation begins.

Sub-cooling and Pressure Reduction: The refrigerant becomes a high-pressure, high-temperature liquid. Sub-cooling prevents liquid flashing as pressure drops in the system. The expansion valve then reduces pressure and temperature further.

Evaporation and Cooling: The refrigerant enters the evaporator, transforming into a saturated liquid and vapor mixture. Warm air heats the refrigerant, causing it to boil and absorb heat. The cycle repeats until the desired temperature is reached.

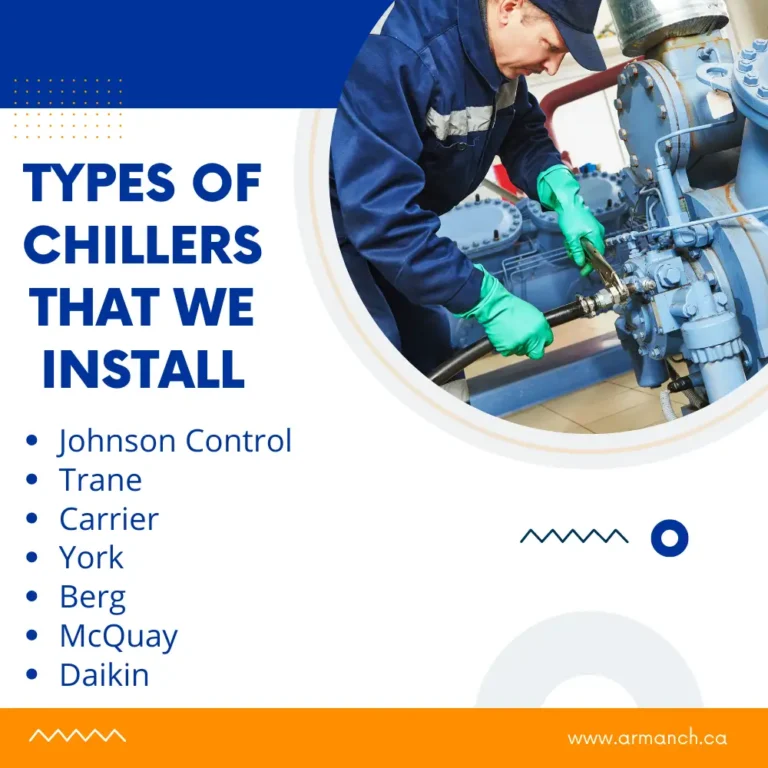

Types of Chillers Installed

Armanch installs and services various types of chillers, including those from major brands like:

Our experts assist in selecting the ideal chiller system for your specific needs, ensuring efficiency and longevity.

Chiller Repairs and Maintenance

We offer prompt chiller repair services to get your equipment running efficiently. Regular maintenance is crucial to ensure maximum efficiency, reduce energy consumption, prevent malfunctions, and extend the chiller’s lifespan. Our preventative maintenance programs are tailored to keep your chiller operating at its best, providing comfort or process cooling as needed.

For urgent service needs or maintenance inquiries, contact Armanch HVAC-R services in GTA. Our skilled technicians are ready to assist with any chiller-related concerns, ensuring optimal performance and reliability.

- HVAC-R

- Design and Permit Services

- Hydronic & Hot Water Services

- Heating and Cooling Services

- Air Conditioning Services