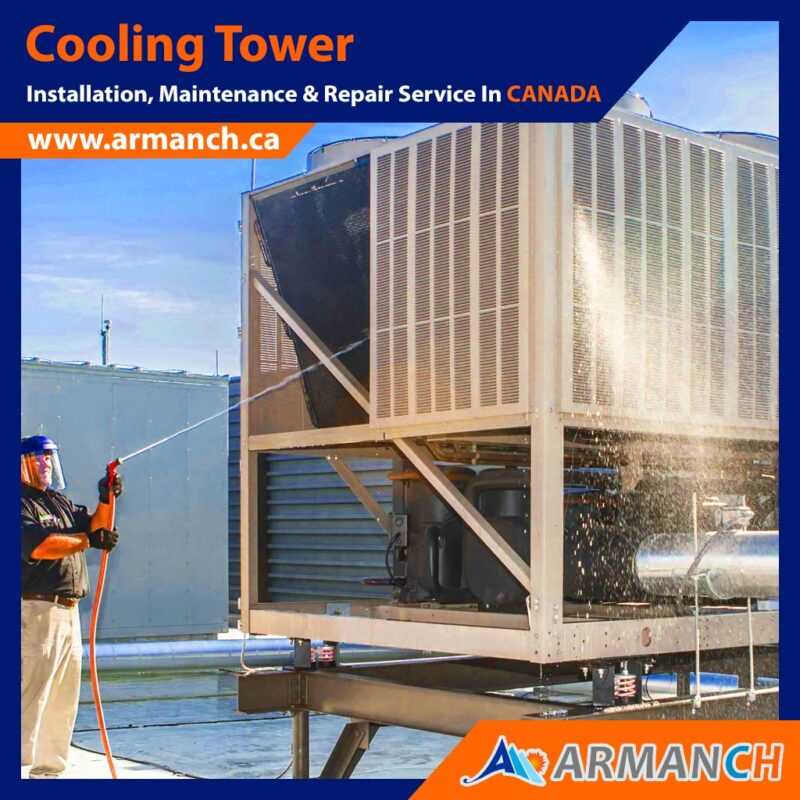

Cooling Tower Repair and Maintenance services in Toronto

Aspects of Cooling Tower Maintenance

Cooling towers are vital components of cooling systems, and proper maintenance is essential for their optimal performance. Here are the key aspects of cooling tower maintenance:

Scale Deposits Removal: Scale buildup on fillers due to minerals in water can hinder the cooling tower’s effectiveness. Regular descaling is necessary to improve energy efficiency, prevent equipment deterioration, and control power consumption costs.

Airflow Optimization: Congested airflow can lead to reduced cooling efficiency, fan performance issues, and system failures. It’s crucial to address loose components, improper fan alignment, or gearbox issues to ensure proper airflow. Regular cleaning and debris removal help maintain optimal airflow.

Cleaning Vents and Tubes: Accumulation of contaminants like sludge, algae, and scale in air intake tubes can block airflow and cause system malfunctions. Routine cleaning and maintenance of vents and tubes are necessary to prevent blockages and maintain system efficiency.

Water Pump Inspection and Maintenance: Water pumps play a crucial role in chiller systems by circulating water for cooling. Properly maintained pumps improve system efficiency, extend equipment life, and ensure smooth operation. Regular inspection, lubrication, and maintenance of pump components are essential.

Water Quality and Treatment: Poor water quality can lead to scale and corrosion issues, causing system failures. Effective water treatment, including testing, treatment with biocides and scale inhibitors, and automated monitoring, is essential to maintain optimal performance and prevent system downtime.

Cooling Towers Repair and Maintenance Services by Armanch

Our knowledgeable specialists at Armanch can assess and handle all aspects of cooling tower and chiller maintenance, ensuring optimal performance, energy efficiency, and system reliability. Contact us for professional cooling tower maintenance services tailored to your specific needs.

- HVAC-R

- Design and Permit Services

- Hydronic & Hot Water Services

- Heating and Cooling Services

- Air Conditioning Services