Optimize Your Space with Efficient Tube Heating Solutions

Efficient Tube Heating Solutions

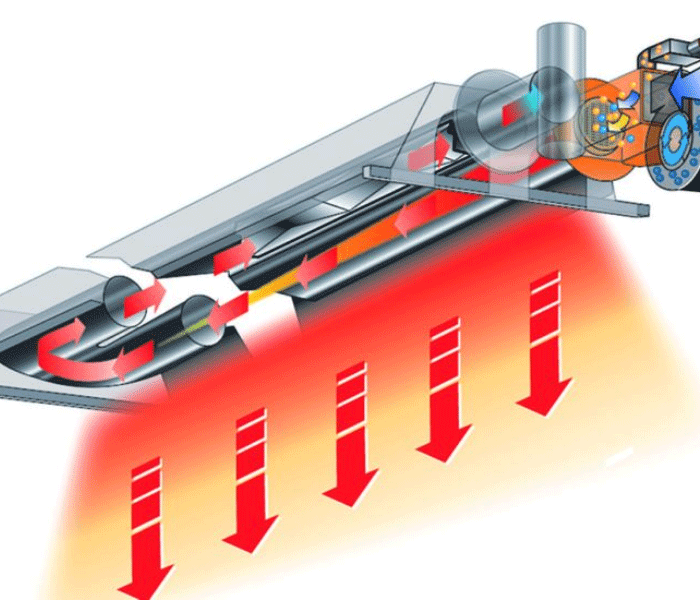

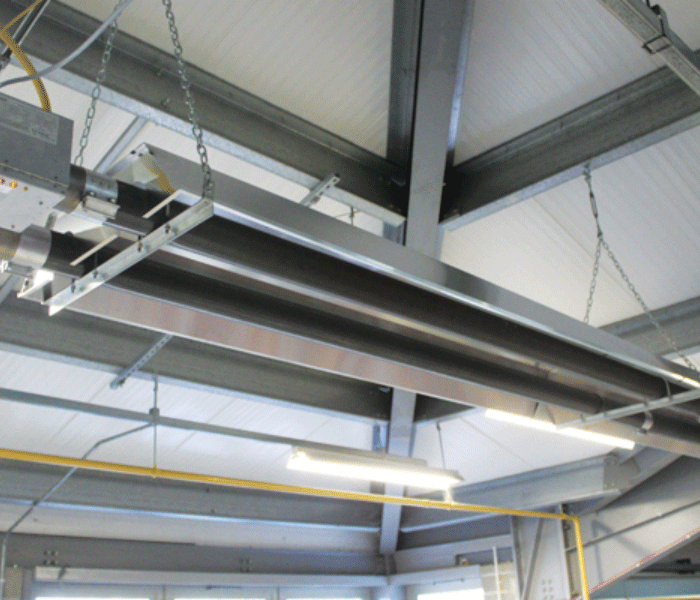

A tube heater is a radiant heating system composed of metal tubes heated by electric elements or burners, emitting heat into the space. Available in various sizes and styles, these heaters find applications in residential, commercial, industrial, and agricultural settings. Commonly used in warehouses, garages, workshops, and even agricultural and greenhouse environments, tube heaters offer effective and versatile heating solutions.

Tube Heaters Efficiency

Tube heaters are renowned for their efficiency in converting energy into heat. These heaters utilize electric heating elements or burners to warm a series of metal tubes, radiating warmth into the surrounding space.

Operating at high temperatures, tube heaters can swiftly and effectively heat a space.

Notably, they use radiant heat, directly warming objects and surfaces, creating a comfortable and energy-efficient environment.

Compared to forced-air heating systems, tube heaters are generally more efficient as they don’t require fans for air circulation. However, efficiency depends on factors like heater size, temperature settings, and the insulation and ventilation of the heated space.

Tube Heaters Advantage

Cost-effective and efficient, tube heaters operate at high temperatures, using radiant heat instead of convection. This approach directly warms surfaces, fostering a more comfortable and energy-efficient heating environment. In settings where traditional forced-air systems prove impractical, tube heaters shine.

Are Tube Heaters Expensive to Run?

The running cost of a tube heater depends on factors such as size, temperature settings, and the insulation and ventilation of the space.

Generally considered cost-effective and efficient due to their use of radiant heat, tube heaters can become expensive if operated at high temperatures for extended periods.

Proper usage, coupled with adequate insulation and ventilation, maximizes energy efficiency, making tube heaters an economical choice.

Do Tubular Heaters Use Much Electricity?

Tubular heaters, or tube heaters, can consume significant electricity if operated at high temperatures for prolonged durations. Their energy usage hinges on size, temperature settings, and the insulation and ventilation of the space.

While they are more efficient and cost-effective than traditional forced-air systems, proper usage, insulation, and ventilation are crucial for optimal performance. The absence of fans for air circulation adds to their energy efficiency.

Can You Leave a Tubular Heater on All the Time?

While tubular heaters can run for extended periods, it’s not advisable to leave them on continuously. Continuous operation increases energy usage, leading to higher bills and safety risks. Extended use may cause overheating, potentially shortening the heater’s lifespan.

It’s recommended to use tubular heaters only when necessary, turning them off when the area is not in use. Employing a programmable thermostat or timer enhances efficiency, ensuring the heater operates only when required, and balancing energy consumption and safety.

Tube heaters offer efficient and affordable heating solutions, especially in scenarios where traditional forced-air systems are impractical or inefficient. Proper usage and maintenance are key to maximizing their benefits.

- HVAC-R

- Design and Permit Services

- Hydronic & Hot Water Services

- Heating and Cooling Services

- Air Conditioning Services